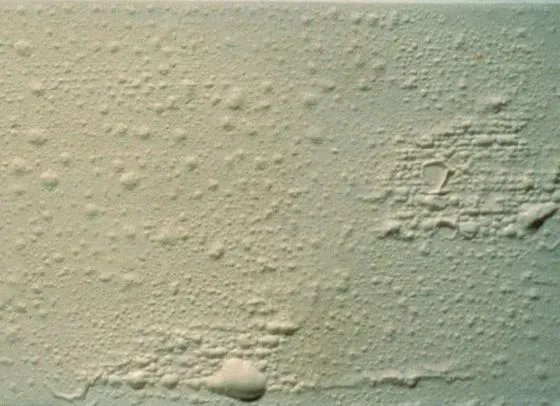

BLISTERING

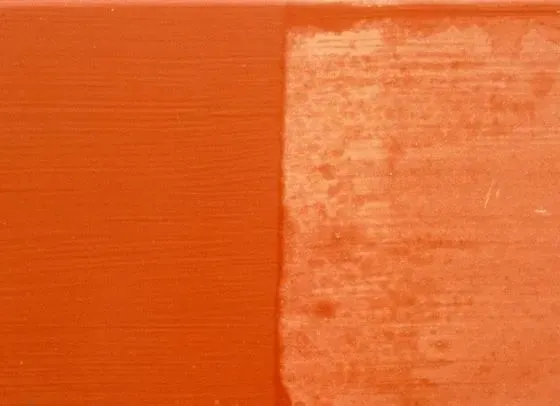

BLISTERING: Bubbles resulting from localized loss of adhesion, and lifting of the paint film from the underlying surface.

POSSIBLE CAUSES: Applying oil-based or alkyd paint over a damp or wet surface. Moisture seeping into the home through the exterior walls (less likely with latex paint). Exposure of latex paint film to high humidity or moisture shortly after paint has dried, especially if there was inadequate surface preparation.

SOLUTION: If blisters do not go all the way down to the substrate, remove blisters by scraping, and sanding, and repaint with a quality acrylic latex interior paint. If blisters go down to the substrate, remove the source of moisture, if possible. Repair loose caulking; consider installing vents or exhaust fans. Remove blisters as above, remembering to prime before applying the top coat BLOCKING undesirable sticking together of two painted surfaces when pressed together (e.g., a door sticking to the jamb).

POSSIBLE CAUSES: Not allowing sufficient dry time for the coating before closing doors or windows. Use of low-quality semi-gloss or gloss paints.

SOLUTION: Use top-quality semi-gloss or gloss acrylic latex paint. Low-quality latex paints can have poor block resistance, especially in warm, damp conditions. Follow paint label instructions regarding dry times. Acrylic latex paints generally have better early block resistance than vinyl latex paints or alkyd or oil-based paints; however, alkyds develop superior block resistance over time. Application of talcum powder can relieve persistent blocking.

BURNISHING

BURNISHING: Increase in gloss or sheen of paint film when subjected to rubbing, scrubbing, or having an object brush up against it.

POSSIBLE CAUSES: Use of flat paint in high-trafficked areas, where a higher sheen level would be desirable. Frequent washing and spot cleaning. Objects (furniture, for example) rubbing against the walls. Use of lower grades of paint with poor stain and scrub resistance (see Poor Stain Resistance and Poor Scrub Resistance)

SOLUTION: Paint heavy wear areas that require regular cleaning (e.g., doors, window sills and trim) with a top-quality latex paint, because this type of paint offers both durability and easier cleaning capability. In high-traffic areas, choose a semigloss or gloss rather than a flat sheen level. Clean painted surfaces with a soft cloth or sponge and non-abrasive cleansers; rinse with clean water.

CRACKING & FLAKING

CRACKING & FLAKING: The splitting of a dry paint film through at least one coat as a result of aging, which ultimately will lead to complete failure of the paint. In its early stages, the problem appears as hairline cracks; in its later stages, flaking occurs.

POSSIBLE CAUSES: Use of lower-quality paint that has inadequate adhesion and flexibility. Over thinning or overspreading the paint. Inadequate surface preparation, or applying the paint to bare wood without first applying a primer. Excessive hardening and embrittlement of alkyd paint as the paint job ages.

SOLUTION: Remove loose and flaking paint with a scraper or wire brush, sanding the surface and feathering the edges. If the flaking occurs in multiple layers of paint, use of a filler may be necessary. Prime bare wood areas before repainting. Use of a quality primer and top coat should prevent a recurrence of the problem.

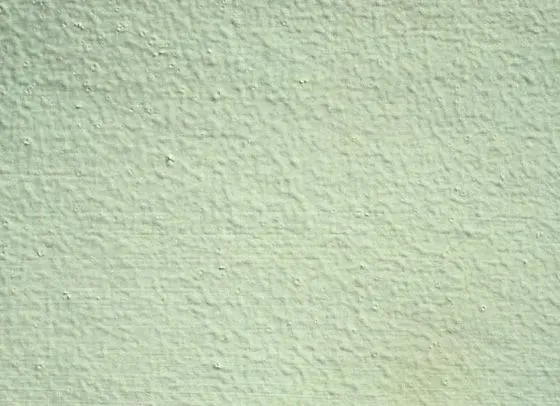

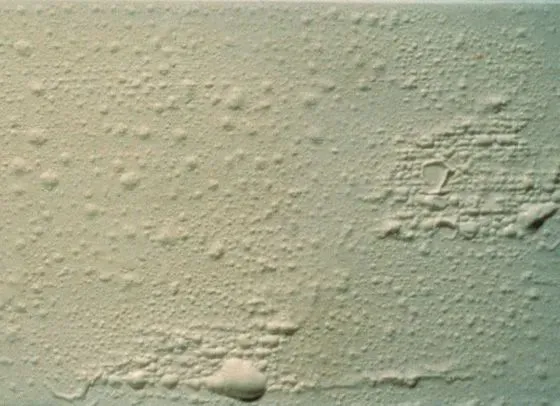

FOAMING & CRATERING

FOAMING & CRATERING: Formation of bubbles (foaming) and resulting small, round concave depressions (cratering) when bubbles break in a paint film, during paint application and drying.

POSSIBLE CAUSES: Shaking a partially filled can of paint. Use of low-quality paint or very old latex paints. Applying (especially rolling) paint too rapidly. Excessive rolling or brushing of the paint. Applying a gloss or semigloss paint over a porous surface.

SOLUTION: All paints will foam to some degree during application; however, higher-quality paints are formulated so the bubbles break while the paint is still wet, allowing for good flow and appearance. Avoid excessive rolling or brushing of the paint or using paint that is more than a year old. Apply gloss and semigloss paints with a short nap roller, and apply an appropriate sealer or primer before using such paint over a porous surface. Problem areas should be sanded before repainting.

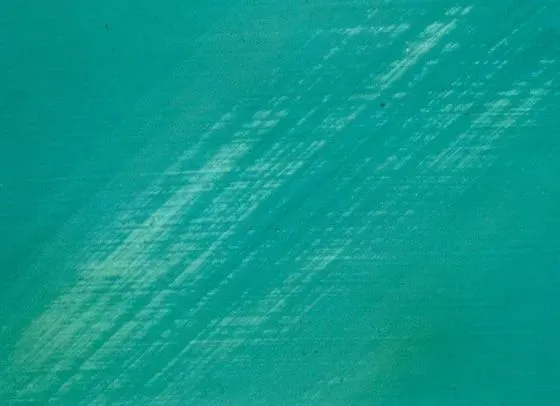

LAPPING

LAPPING: Appearance of a denser color or increased gloss where wet and dry layers overlap during paint application.

POSSIBLE CAUSES: Failure to maintain a “wet edge” when painting. Use of a low solids “economy” paint.

SOLUTION: Maintain a wet edge when painting by applying paint toward the unpainted area and then back into the just-painted surface. This technique (brushing or rolling from “wet to dry” rather than vice versa) will produce a smooth uniform appearance. It is also wise to work in manageable size areas; plan for interruptions at a natural break, such as a window, door or corner. Using a top-quality acrylic latex paint makes it easier to avoid lapping problems because higher solid (pigments and binder) content makes lapped areas less noticeable. If the substrate is very porous, it may need a primer/sealer to prevent paint from drying too quickly and reducing wet edge time. Alkyd paints generally have superior wet edge properties.

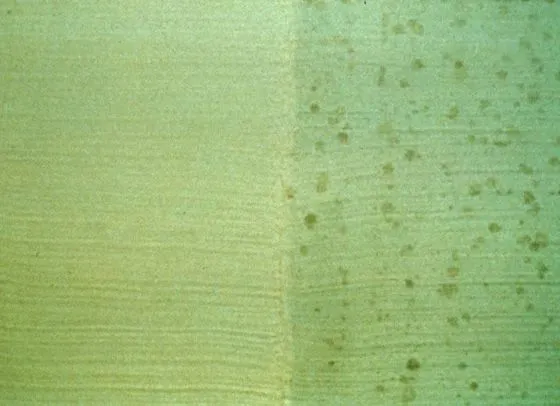

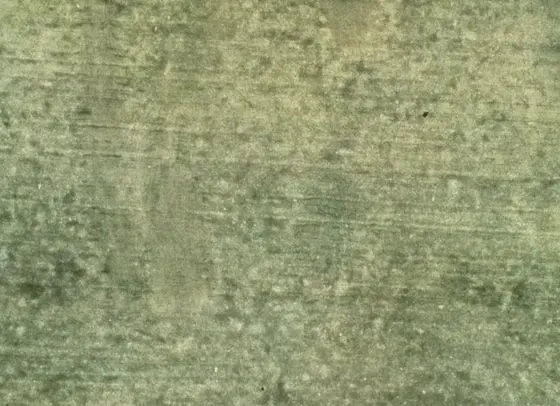

MILDEW

MILDEW: Black, gray, or brown spots or areas on the surface of paint or caulk.

POSSIBLE CAUSES: Forms most often on areas that tend to be damp, or receive little or no direct sunlight (e.g., bathrooms, kitchens, and laundry rooms). Use of an alkyd or oil-based paint, or lower-quality latex paint. Failure to prime bare wood surface before applying the paint. Painting over a substrate or coating on which mildew has not been removed.

SOLUTION: Test for mildew by applying a few drops of household bleach to the area; if it is bleached away, the discolorant is probably mildew. Remove all mildew from the surface by scrubbing with a diluted household bleach solution (one part bleach, three parts water), while wearing rubber gloves and eye protection. Rinse thoroughly. To protect against mildew, use a quality latex paint, and clean when necessary with bleach/detergent solution. Consider installing an exhaust fan in high-moisture areas.

MUD CRACKING

MUD CRACKING: Deep, irregular cracks resembling dried mud in the dry paint film.

POSSIBLE CAUSES: Paint applied too thickly, usually over a porous surface. Paint applied too thickly, to improve inherent poor hiding (coverage) of a lower-quality paint. Paint is allowed to build up in corners upon application.

SOLUTION: Remove coating by scraping and sanding. Prime and repaint, using a quality latex paint. Mud-cracked areas can also be repaired by sanding the surface smooth before repainting with a quality latex paint. This type of paint is likely to prevent recurrence of mud cracking because it is relatively more flexible than alkyd paint, oil-based paint, and ordinary latex paint. Quality paints have a higher solid content, which reduces the tendency to mud crack. They also have very good application and hiding properties, which minimize the tendency to apply too thick a coat of paint.

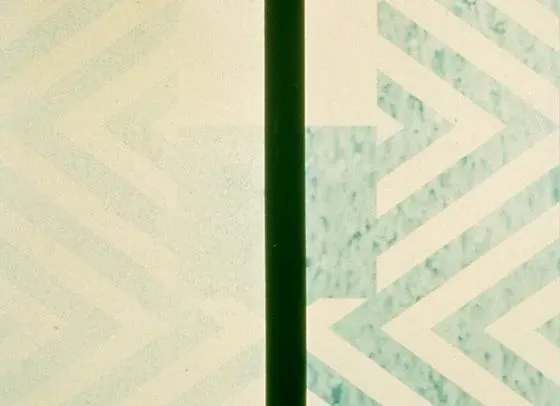

PICTURE FRAMING

PICTURE FRAMING: An effect of non-uniform color that can appear when a wall is painted with a roller but is brushed at the corners. The brushed areas generally appear darker, resembling the “frame” of a “picture.” Also, sprayed areas may be darker than neighboring sections that are brushed or rolled. Picture framing can also refer to sheen effects.

POSSIBLE CAUSES: Usually a hiding (coverage) effect. Brushing will generally result in lower spread rates than rolling, producing a thicker film and more hiding. Adding colorant to a non-tintable paint or using the wrong type or level of colorant, resulting in variation in color, depending on the method of application.

SOLUTION: Make sure that spread rates with brushes and rollers are similar. Don’t cut in the entire room before roller coating. Work in smaller sections of the room to maintain a “wet edge.” With tinted paints, be sure the correct colorant-base combinations are used. Factory colors, as well as in-store tints, should be thoroughly shaken at the time of sale.

POOR HIDING

POOR HIDING: Failure of dried paint to obscure or “hide” the surface to which it is applied.

POSSIBLE CAUSES: Use of low-quality paint. Use of low-quality tools/wrong roller cover. Use of an improper combination of tinting base and tinting color. Poor flow and leveling (see Poor Flow/Leveling). Use of a paint that is much lighter in color than the substrate, or that primarily contains low-hiding organic pigments. Application of paint at a higher spread rate than recommended.

SOLUTION: If the substrate is significantly darker or is a patterned wallpaper, it should be primed before applying a top coat. Use a quality paint for better hiding and flow. Use quality tools; use the recommended roller nap, if rolling. Follow manufacturer’s recommendation on spread rate; if using tinted paint, use the correct tinting base. Where a low-hiding organic color must be used, apply a primer first.

POOR SCRUB RESISTANCE

POOR SCRUB RESISTANCE: Tendency of the paint film to take on the imprint of an object that is placed on it (e.g., a shelf, table, windowsill, or countertop with books, dishes, and other objects on them).

POSSIBLE CAUSES: Use of low-quality semi-gloss or gloss paint. Putting a painted surface back into use before the paint has fully dried.

SOLUTION: Use top-quality acrylic semi-gloss or gloss latex paint. Low-quality latex semi-gloss and gloss paints can have poor print resistance, especially in warm, damp conditions. Acrylic latex paints generally have better print resistance than vinyl latex paints. Fully cured alkyd paints also have excellent print resistance. Make sure the recommended “cure” time is allowed for the paint before it is put into service. Cool or humid conditions require more curing time.

POOR STAIN RESISTANCE

POOR STAIN RESISTANCE: Failure of the paint to resist absorption of dirt and stains

POSSIBLE CAUSES: Use of lower-quality paint that is porous in nature. Application of paint to un-primed substrate.

SOLUTION: Higher-quality latex paints contain more binder, which helps prevent stains from penetrating the painted surface, allowing for easy removal. Priming new surfaces provide the maximum film thickness of a premium top coat, providing very good stain removability.

POOR SHEEN UNIFORMITY

POOR SHEEN UNIFORMITY: Shiny spots or dull spots (also known as “flashing”) on a painted surface; uneven gloss.

POSSIBLE CAUSES: Uneven spread rate. Failure to properly prime a porous surface, or surface with varying degrees of porosity. Poor application resulting in lapping (see Lapping).

SOLUTION: New substrates should be primed/sealed before applying the top coat to ensure a uniformly porous surface. Without the use of a primer or sealer, a second coat of paint will more likely be needed. Make sure to apply paint from “wet to dry” to prevent lapping. Often, applying an additional coat will even out sheen irregularities.

SAGGING

SAGGING: Downward “drooping” movement of the paint film immediately after application, resulting in an uneven coating.

POSSIBLE CAUSES: Application of a heavy coat of paint. Application in excessively humid and/or cool conditions. Application of over thinned paint. Airless spraying with the gun too close to the substrate being painted.

SOLUTION: If the paint is still wet, immediately brush out or re-roll to redistribute the excess evenly. If the paint has dried, sand and reapply a new coat of top-quality paint. Correct any unfavorable conditions: Do not thin the paint; avoid cool or humid conditions; sand glossy surfaces. Paint should be applied at its recommended spread rate; avoid “heaping on” the paint. Two coats of paint at the recommended spread rate are better than one heavy coat, which can also lead to sagging. Consider removing doors to paint them supported horizontally.

WRINKLING

WRINKLING: A rough, crinkled paint surface, which occurs when uncured paint forms a “skin.”

POSSIBLE CAUSES: Paint applied too thickly (more likely when using alkyd or oil-based paints). Painting during extremely hot weather or cool damp weather, which causes the paint film to dry faster on top than on the bottom. Exposing uncured paint to high humidity levels. Painting over a contaminated surface (e.g., dirt or wax).

SOLUTION: Scrape or sand substrate to remove the wrinkled coating. If using a primer, allow it to dry completely before applying the top coat. Repaint (avoiding temperature/humidity extremes), applying an even coat of top-quality interior paint.

YELLOWING

YELLOWING: Development of a yellow cast in aging paint; most noticeable in the dried films of white paints or clear varnishes.

POSSIBLE CAUSES: Oxidation of alkyd or oil-based paint or varnish. Heat from stoves, radiators, and heating ducts. Lack of light (e.g., behind pictures or appliances, inside closets, etc.).

SOLUTION: Top-quality latex paints do not tend to yellow, nor does non-yellowing varnish. Alkyd paints, because of their curing mechanism, do tend to yellow, particularly in areas that are protected from sunlight.

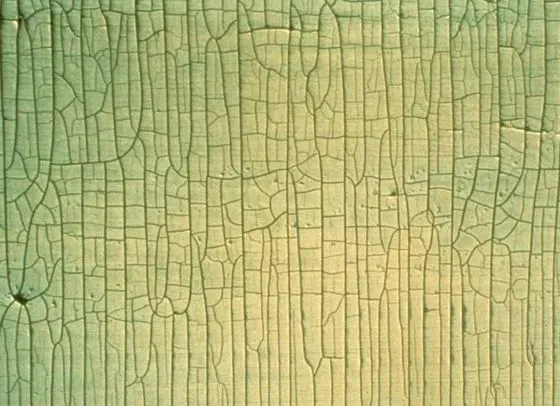

ALLIGATORING

ALLIGATORING: Patterned cracking in the surface of the paint film resembling the regular scales of an alligator.

POSSIBLE CAUSES: Application of an extremely hard, rigid coating, like an alkyd enamel, over a more flexible coating, like a latex primer. Application of a topcoat before the undercoat is dry. Natural aging of oil-based paints as temperatures fluctuate. The constant expansion and contraction results in a loss of paint film elasticity.

SOLUTION: Old paint should be completely removed by scraping and sanding the surface; a heat gun can be used to speed work on large surfaces, but take care to avoid igniting paint or substrate. The surface should be primed with high-quality latex or oil-based primer, then painted with a top-quality exterior latex paint.

BLISTERING

BLISTERING: Bubbles resulting from localized loss of adhesion, and lifting of the paint film from the underlying surface

POSSIBLE CAUSES: Applying oil-based or alkyd paint over a damp or wet surface. Moisture seeping into the home through the exterior walls (less likely with latex paint). Exposure of latex paint film to high humidity or moisture shortly after paint has dried, especially if there was inadequate surface preparation.

SOLUTION: If blisters do not go all the way down to the substrate: Remove blisters by scraping and sanding, and repaint with a quality acrylic latex interior paint. If blisters go down to the substrate: Remove the source of moisture, if possible. Repair loose caulking; consider installing vents or exhaust fans. Remove blisters as above, remembering to prime before applying the top coat.

CHALKING

CHALKING: Formation of fine powder on the surface of the paint film during weathering which can cause color fading. Although some degree of chalking is a normal, desirable way for a paint film to wear, excessive film erosion can result from heavy chalking.

POSSIBLE CAUSES: Use of a low-grade, highly pigmented paint. Use of an interior paint for an outdoor application.

SOLUTION: First, remove as much of the chalk residue as possible, scrubbing with a stiff bristle brush (or wire brush on masonry) and then rinse thoroughly; or use power washing equipment. Check for any remaining chalk by running a hand over the surface after it dries. If noticeable chalk is still present, apply a quality oil-based or acrylic latex primer (or comparable sealer for masonry), then repaint with a quality exterior coating; if little or no chalk remains and the old paint is sound, no priming is necessary.

CRACKING & FLAKING

CRACKING & FLAKING: The splitting of a dry paint film through at least one coat, which will lead to complete failure of the paint. Early on, the problem appears as hairline cracks; later, flaking of paint chips occurs.

POSSIBLE CAUSES: Use of a lower quality that has inadequate adhesion and flexibility. Over-thinning the paint or spreading it too thin. Poor surface preparation, especially when the paint is applied to bare wood without priming. Painting under cool or windy conditions that make latex paint dry too fast.

SOLUTION: It may be possible to correct cracking that does not go down to the substrate by removing the loose or flaking paint with a scraper or wire brush, sanding to feather the edges, priming any bare spots and repainting. If the cracking goes down to the substrate remove all of the paint by scraping, sanding and/or use of a heat gun; then prime and repaint with a quality exterior latex paint. DIRT PICKUP Accumulation of dirt, dust particles and/or other debris on the paint film; may resemble mildew.

POSSIBLE CAUSES: Use of a low-quality paint, especially lower grades of satin or semigloss. Soil splashing onto the siding. Air pollution, car exhaust, and flying dust collecting on house body and horizontal trim.

SOLUTION: Wash off all surface dirt before priming and painting, using a scrub brush and detergent solution, followed by a thorough rinsing with a garden hose. Heavier dirt accumulations may require the use of a power washer. While dirt pickup can’t be eliminated entirely, top-quality exterior latex paints typically offer superior dirt pickup resistance and washability. Also, higher gloss paints are more resistant to dirt pickup than flat paints, which are more porous and can more easily entrap dirt.

EFFLORESCENCE & MOTTLING: Crusty, white salt deposits, leached from mortar or masonry as water passes through it.

POSSIBLE CAUSES: Failure to adequately prepare the surface by removing all previous efflorescence. Excess moisture escaping through the exterior masonry walls from behind.

SOLUTION: If excess moisture is the cause, eliminate the source by repairing the roof, cleaning out gutters and downspouts, and sealing any cracks in the masonry with a high-quality, water-based all-acrylic or siliconized acrylic caulk. If moist air is originating inside the building, consider installing vents or exhaust fans, especially in kitchen, bathroom, and laundry areas. Remove the efflorescence and all other loose material with a wire brush, power brush, or power washer; then thoroughly rinse the surface. Apply a quality water-based or solvent-based masonry sealer or primer, and allow it to dry completely; then apply a coat of top-quality exterior house paint, masonry paint, or elastomeric wall coating.

FADING

FADING: Premature and/or excessive lightening of the paint color, which often occurs on surfaces with sunny southern exposure. Fading/poor color retention can also be a result of chalking of the coating.

POSSIBLE CAUSES: Use of an interior grade of paint for an outdoor application. Use of a lower-quality paint, leading to rapid degradation (chalking) of the paint film. Use of a paint color that is particularly vulnerable to UV radiation (most notably certain bright reds, blues, and yellows). Tinting a white paint not intended for tinting, or overtinting a light or medium paint base.

SOLUTION: When fading/poor color retention is a result of chalking, it is necessary to remove as much of the chalk as possible (see Chalking). In repainting, be sure to use a quality exterior house paint in colors recommended for exterior use.

FROSTING

FROSTING: A white, salt-like substance on the paint surface. Frosting can occur on any paint color, but it is less noticeable on white paint or lighter tints. On masonry, it can be mistaken for efflorescence (see Efflorescence and Mottling).

POSSIBLE CAUSES: Forms mostly in protected areas (such as under eaves and on porch ceilings) that do not receive the cleansing action of rain, dew, and other moisture. Use of dark-colored paints that have been formulated with calcium carbonate extender. Application of a dark-colored paint over a paint or primer containing calcium carbonate extender.

SOLUTION: Frosting can be a stubborn problem. It often cannot be washed off readily. Moreover, the condition can recur even as a bleed-through when a new top coat is applied. In extreme cases, it can interfere with adhesion. The best remedy is to remove the frosting by wire brushing masonry or sanding wood surfaces; rinse, then apply an alkyd-based primer before adding a coat of high-quality exterior paint.

PAINT INCOMPATIBILITY: Loss of adhesion where many old coats of alkyd or oil-based paint receive a latex top coat.

POSSIBLE CAUSES: Use of water-based latex paint over more than three or four coats of old alkyd or oil-based paint may cause the old paint to “lift off” the substrate.

SOLUTION: Repaint using another coat of alkyd or oil-based paint. Or completely remove the existing paint and prepare the surface – cleaning, sanding, and spot-priming where necessary – before repainting with a top-quality latex exterior paint.

LAPPING

LAPPING: Appearance of a denser color or lighter gloss where wet and dry layers overlap during paint application.

POSSIBLE CAUSES: Failure to maintain a “wet edge” when painting.

SOLUTION: Maintain a wet edge when painting by applying paint toward the unpainted area and then back into the just-painted surface. This technique (brushing from “wet to dry” rather than vice versa) will produce a smooth uniform appearance. It is also wise to minimize the area being painted, and plan for interruptions at a natural break, such as a window, door, or corner (especially important when applying stain to bare wood). Alkyd paints generally have superior wet edge properties.

MILDEW

MILDEW: Black, gray, or brown areas of fungus growth on the surface of paint or caulk.

POSSIBLE CAUSES: Forms most often on areas that tend to be damp, and receive little or no direct sunlight (walls with a northerly exposure and the underside of eaves are particularly vulnerable). Use of a lower-quality paint, which may have an insufficient amount of mildewcide. Failure to prime bare wood before painting. Painting over a substrate or coating on which mildew has not been removed.

SOLUTION: Test to distinguish mildew from dirt by applying a few drops of household bleach to the discolored area; if it disappears, it is probably mildew. Treat the mildew by applying a mixture of water and bleach, 3:1, and leave on for 20 minutes, applying more as it dries. Wear goggles and rubber gloves. Then scrub and rinse the area. Apply an exterior latex primer, then a top-of-the-line exterior latex paint in flat, satin, semigloss, or gloss finish, depending on the desired appearance.

PEELING

PEELING: Loss of paint due to poor adhesion. Where there is a primer and top coat, or multiple coats of paint, peeling may involve some or all coats.

POSSIBLE CAUSES: Seepage of moisture through uncaulked joints, worn caulk, or leaks in roof or walls. Excess moisture escaping through the exterior walls (more likely if paint is oil-based). Inadequate surface preparation. Use of lower-quality paint. Applying an oil-based paint over a wet surface. Earlier blistering of paint (see Blistering).

SOLUTION: Try to identify and eliminate the source of moisture. Prepare the surface by removing all loose paint with a scraper or stiff wire brush, sand rough edges, and apply appropriate primer. Repaint with a top-quality acrylic latex exterior paint for best adhesion and water resistance.

POOR GALVANIZED METAL ADHESION

POOR GALVANIZED METAL ADHESION: Paint that has lost its adhesion to a galvanized metal substrate.

POSSIBLE CAUSES: Improper surface preparation, such as inadequate rust removal. Failure to apply a primer before application of an oil-based or vinyl latex paint. Failure to sand baked-on enamel finishes or glossy surfaces before painting.

SOLUTION: Any rust on the metal should be removed with a wire brush; then, an acrylic latex corrosion-inhibitive primer should be applied (one coat is usually sufficient). Previously painted galvanized metal that is completely rust-free can be painted without applying a primer. A latex metal primer should be applied to unpainted galvanized metal, followed by a top-quality exterior acrylic latex paint.

POOR GLOSS RETENTION

POOR GLOSS RETENTION: Deterioration of the paint film, resulting in excessive or rapid loss of luster of the top coat.

POSSIBLE CAUSES: Use of an interior paint outdoors. Use of a lower-quality paint. Use of a gloss alkyd or oil-based paint in areas of direct sunlight.

SOLUTION: Direct sunshine can degrade the binder and pigment of a paint, causing it to chalk and lose its gloss. While all types of paint will lose some degree of luster over trim, lower-quality paints will generally lose gloss much earlier than better grades. The binder in top-quality acrylic latex paints is especially resistant to UV radiation, while oil and alkyd binders actually absorb the radiation, causing the binders to break down. Surface preparation for a coating showing poor gloss retention should be similar to that used for chalking surfaces (see Chalking).

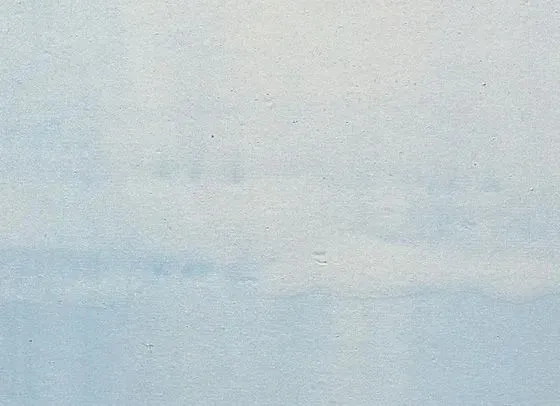

SURFACTANT LEACHING

SURFACTANT LEACHING: Concentration of water-soluble ingredients on latex paint, creating a blotchy, sometimes glossy appearance, often with a tan or brownish cast. More likely with tinted paints than with white or factory-colored paints.

POSSIBLE CAUSES: Painting in cool, humid conditions or just before they occur. The longer drying time allows the paint’s water-soluble ingredients – which would normally evaporate, or be leached out by rain or dew – to rise to the surface before paint thoroughly dries. Mist, dew, or other moisture drying on the painted surface shortly after it has dried.

SOLUTION: Avoid painting in the late afternoon if cool, damp conditions are expected in the evening or overnight. If the problem occurs in the first day or so after the paint is applied, the water-soluble material can sometimes be rinsed off rather easily. Fortunately, even more stubborn cases will generally weather off in a month or so. Surfactant leaching should not affect the ultimate durability of the coating.

VINYL SIDING WARP: Warping or buckling of vinyl siding panels that have been repainted.

POSSIBLE CAUSES: Most likely cause is that vinyl siding was painted with a darker color paint than the original color. Dark paint tends to absorb the heat of the sun, transferring it to the substrate. When vinyl siding expands dramatically, it is not able to contract to its original dimensions.

SOLUTION: Paint vinyl siding in a shade no darker than the original. Whites, off-whites, pastels, and other very light colors are good choices. Top-quality acrylic latex paint is the best type of paint to use on vinyl siding because the superior flexibility of the paint film enables it to withstand the stress of expansion and contraction cycles caused by outdoor temperature changes. Siding that has warped or buckled should be assessed by a siding or home repair contractor to determine the best remedy. The siding may have to be replaced.

WAX BLEED

WAX BLEED: Stains that come from waxy substance in the reconstituted wood products used to make hardboard siding. When the substrate is painted, these staining substances bleed through the paint; they can even bleed through some ordinary primers, possibly causing dirt pickup, mildew, and/or poor paint adhesion (see Dirt Pickup and Mildew).

POSSIBLE CAUSES: Failure to apply a proper primer to the hardboard before applying the top coat. Allowing hardboard siding to weather before being painted.

SOLUTION: To treat or prevent, apply a quality exterior acrylic latex primer; follow with a coat of high-quality exterior acrylic latex paint. The American Hardboard Association recommends two coats of top-quality acrylic exterior house paint for best results. Some hardboard grades have adequate factory primers and need only a quality paint applied. Low-quality, highly pigmented flat paints are more prone to wax bleed than are higher-quality paints.